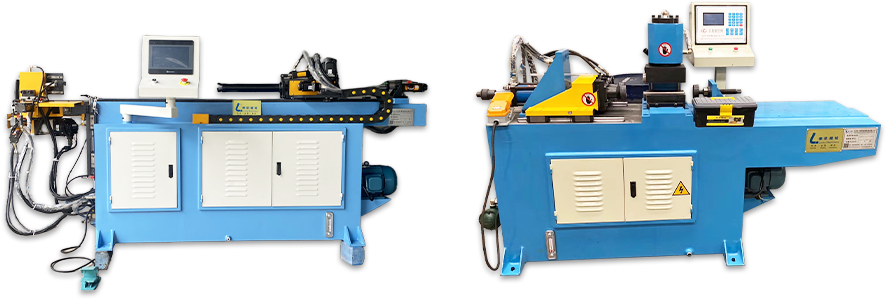

專業制造管類加工機械設備

彎管 切管 管端成型 管型材專業設備制造 >>

彎管 切管 管端成型 管型材專業設備制造 >>

A, the machine model beautiful, delicate, provides maximum elbow room.

B, single-chip computer control point mode, people, machine dialogue operation, convenient and flexible.

C, bending angle encoder track and the use of feedback information, the bending angle accuracy.

D, store multiple sets of processing mode, flexible switching between programs with different specifications.

E, with automatic counting and intended function of power in mind.

F, equipped with a hydraulic cooling system to ensure stable operation of the machine for a long time.

G, the unique air-cooled and water cooled design, to ensure the stability of the hydraulic system; unique copper on both sides of the slider, the slider will not wear the nose.

A、 機器造型美觀、精巧,提供了最大彎管空間。

B、 采用單片機控制角摸式人、機對話操作,方便靈活。

C、 彎曲角度采用編碼器跟蹤并回饋信息,彎曲角度精度高。

D、 存儲多組加工模式,不同規格程序之間靈活切換。

E、 具有自動記數和停電記意功能。

F、 配備液壓冷卻系統,保證機器長時間穩定工作。

Maximum bending capacity mm | Φ219× 12 |

Bending radius (mm) | 350-1100 |

Maximum bending angle | 185 ° |

Maximum pressure (Mpa) | 14 |

Hydraulic system motor (kw) | 2*22 |

Through the effective core length (mm) | 6500 |

Machine dimensions (m) | 9 × 2.5 × 2 |

Weight (kg) | 24000 |

因技術更新,網站所展示內容可能存在誤差,具體詳情請咨詢我們!

版權所有 ? 2024 張家港市樂凱機械制造有限公司蘇ICP備15059511號-3